3D Printing For Post Production

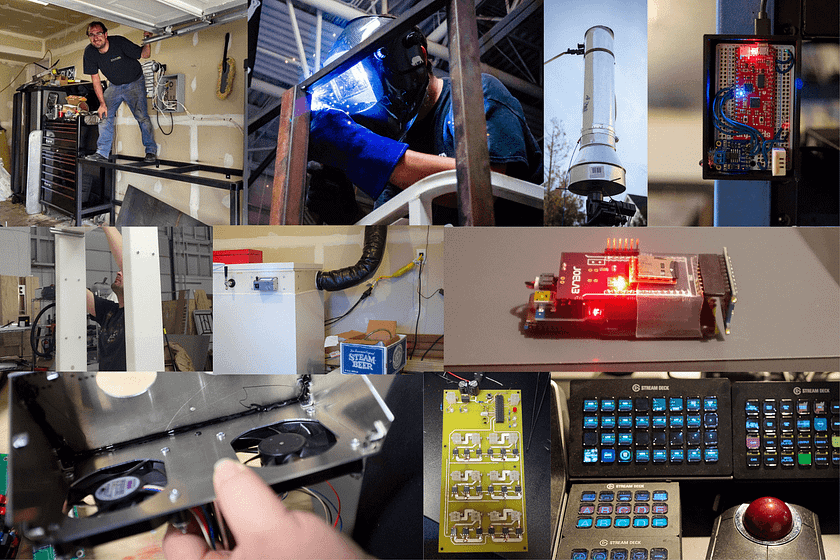

I’ve always been a bit of a tinkerer and maker. I love building my own solutions to problems, my own electronics, tools, etc. If I have a choice between buying something off the shelf or building it myself, I’ll almost always build it myself.

These days – making skills can be useful for any industry, even post-production. In the new age of problem-solving during the Covid pandemic – being able to customize and build things you need for your home studio can be a huge advantage!

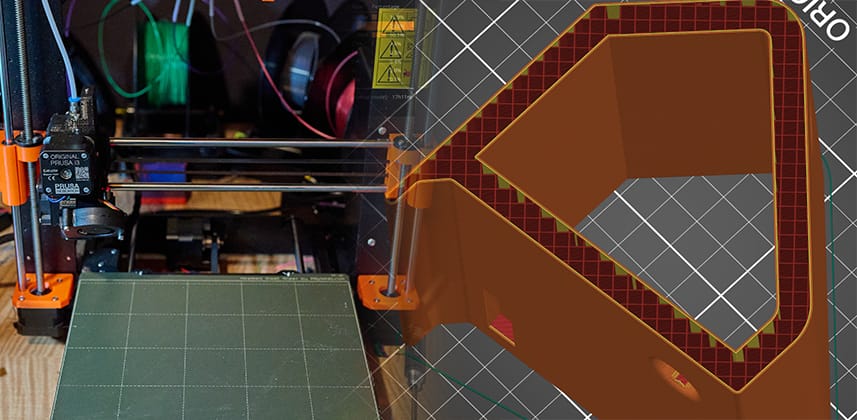

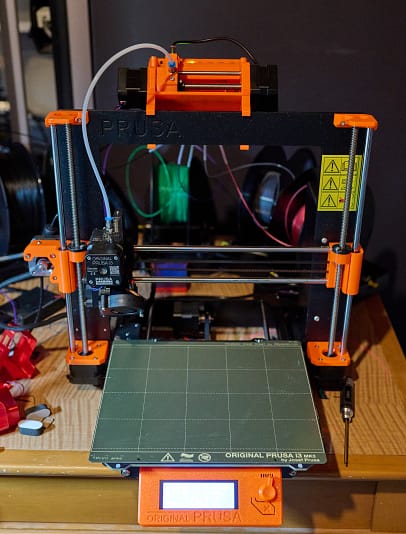

Over the past few years, this has led me into the fascinating world of additive manufacturing, specifically 3D printing. Originally I wanted to print drone parts and toys for my kids. Starting with a cheap entry-level printer, I now have grown to 4 printers and even multi-material capability.

So What Does This Have To Do With Color Grading?

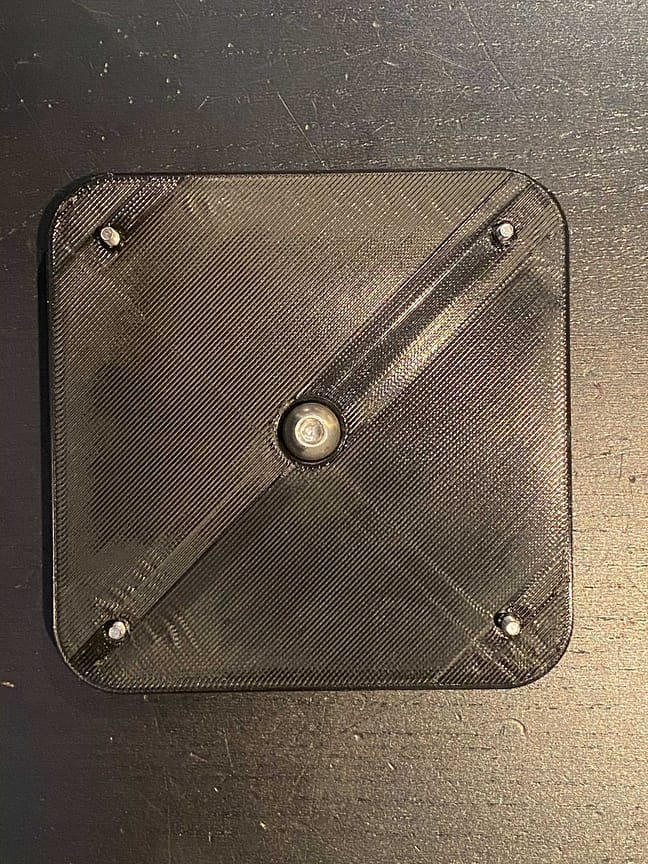

Well, one of the coolest things I’ve been able to do with 3D printing has been customizing my color suite! These days I have a ton of 3D printed adaptors, holders, and devices that make my day to day work much easier. It started with holders for the original Stream deck, and now I have custom holders for the Stream Deck XL that aligns it with my Resolve Mini Panel and with my Element panels on my assist station, adaptor plates for my scope monitor and ATEM monitor, and even Wacom pen holders.

The coolest part? I’ve been able to reach out to other colorists who have printers and give them files to print themselves – from anywhere in the world. Robbie recently needed the same monitor plate as I use for my scopes – and in the age of Covid I can’t just meet up with him at the office anymore. Instead, I sent him a tiny file, and a few hours later he had the exact same physical object. That is some Star Trek level future stuff right there!

3D Printing is also fantastically useful for prototyping. If you need to have some kind of custom mount or stand designed for your suite – but need it to be stronger than a printed part can be, you can test fit lots of different options before paying to have a part professionally made. In my case – we used 3D printed prototypes to verify the fit of a custom adaptor that mounts my XM310K monitor to my TBC console. Obviously – I didn’t want to trust a $25,000 monitor to a 3D printed part – so the final version was machined out of aluminum.

Getting Started

At this point – I’ve sent my printed Stream Deck holders to a lot of colorist friends, but I’ve had even more reach out to me asking how to get started printing their own.

I’ve seen a ton of interest in the post-production community about 3D printing – so I am writing this article to serve as an all-encompassing introduction. I’ll explain the concepts, terms, process, and provide some resources to get started.

One important thing to remember – 3D printing is a complex and evolving field so don’t get disheartened by initial failures or issues. Failed prints can be frustrating but think of them as learning experiences and a chance to improve. This isn’t quite plug and play yet, so expect a bit of tinkering and learning along the way.

So let’s start at the very beginning: what is 3D printing?3D printing is a form of additive manufacturing.

This means producing a physical object by building up raw material (as opposed to traditional machining, where you cut an object out of a bigger piece of raw material). There are many different types of 3D printing – but for our purposes, we are going to focus on FDM (fused deposition modeling) printing. This works by melting plastic through a small nozzle, and essentially building the object up as a series of individual layers.

Member Content

Sorry... the rest of this content is for members only. You'll need to login or Join Now to continue (we hope you do!).

Need more information about our memberships? Click to learn more.

Membership optionsMember Login